|

|

|

|

|

|

| Foil RF Shielding Tape |

|

|

|

|

Aluminum Foil Tape for EMI / RFI / RF Shielding |

|||||||||||||||||||||||||||||||

With Electrically Conductive Pressure Sensitive Adhesive (ECPSA) |

|||||||||||||||||||||||||||||||

ST2 & AL5 Tape is applied like any tape with a release. The tape is used to RF shield between metal substrates. EMI-SHIELD RF Shielding Tape has aluminum foil backing with a pressure sensitive, electrically conductive, proprietary acrylic adhesive that ensures adherence. The conductive particles in the adhesive offer low resistance between the substrate and the backing. This tape is designed for applications such as static charge draining, seaming shielded rooms, cable wrapping and providing surface contact to non solderable materials. Ideal for RF shielding, grounding and static charge draining.

Environmental Declarations LEED Information UL Environment Meets EMP Protection AL2 Levels: 1, 2, 3 & (lowest level of 4) AL5 Levels: 1, 2, 3, 4 for Infrastructure Shielding Installed EMI-SHIELD AL5 Rolls & Tape

|

|

||||||||||||||||||||||||||||||

Chart below is actual installed electrically conductive AL5 tape, between two sheets of AL5 Foil |

|||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||

Copper Foil Tape for EMI / RFI / RF Shielding |

|||||||||||||||||||||||||||||||||||||||||||||

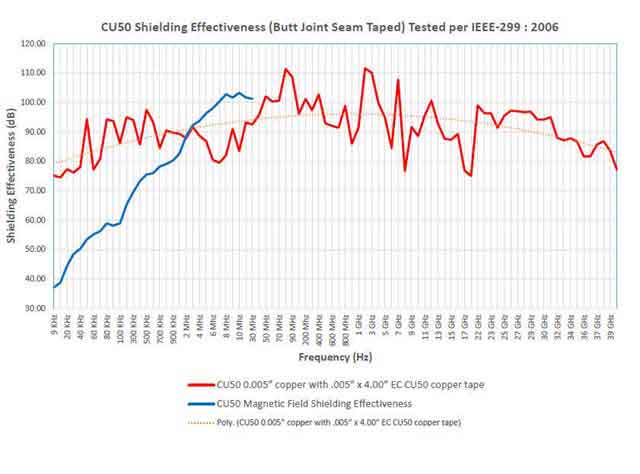

CU14 & CU50 Tape is applied like any tape with a release. The tape is used to RF shield between metal substrates. EMI-SHIELD RF Shielding Tape has copper foil backing with a pressure sensitive, electrically conductive, proprietary acrylic adhesive that ensures adherence. The conductive particles in the adhesive offer low resistance between the substrate and the backing. This tape is designed for applications such as static charge draining, seaming shielded rooms, cable wrapping and providing surface contact to non solderable materials. Ideal for RF shielding, grounding and static charge draining.

Environmental Declarations LEED Information UL Environment Meets EMP Protection CU14 Levels: 1, 2, 3 & (lowest level of 4) CU50 Levels: 1, 2, 3, 4 for Infrastructure Shielding

|

|

||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||

| Concrete Warning |

| Since aluminum is subject to attack by alkaline(s) it should NOT be allowed to come in direct contact with concrete or mortar. If aluminum is in contact with concrete (or even other metals) and is subject to wetting (as would happen outdoors), the aluminum should be insulated from the concrete, mortar, or metal by adding a barrier like: asphalts, paint, sealer, 6 mil plastic polyurethane sheeting or a neoprene adhesive. Use waterproofing concrete sealer if you know water might get in, on or through the concrete. If the aluminum foil shielded room has fire sprinklers installed, it is good idea to water seal the concrete floor, just in case of an intentional or unintentional water discharge. |

|

Copyright © 2001- R. A. Mayes Company, Inc. An Electro Mechanical Research and Development (EMRAD) Corporation, Company See our Privacy Policy All the data files on our website require Adobe Acrobat Reader! |